TABLE OF CONTENTS

- Product Introduction

- Installation instruction

- Charger configuration steps:

- DLM HUB configuration instruction

- Troubleshooting

Important

Read this User Manual before you start using the device!

Failure to comply with these instructions may result in injury, damage to the device, harm to the environment, or other serious issues.

Keep this User Manual in a safe place together with the charging equipment.

Safety Information

Use the DLM HUB only within the specified operating parameters.

Installation with electricity is prohibited, Read the instructions carefully before installation.

Do not attempt to open, disassemble, repair, tamper with, or modify the device. The Device is not user serviceable. Please contact MOREK for any issues.

Scope of supply

DLM HUB Controller *1

120Ω Resistance *1

CT clamp *1 or 3 (optional)

100 m Twisted-pair cabling *1(optional)

Product Introduction

Application

The DLM HUB DLB controller maximizes the usage of grid, it will distribute the current into each and every charger equally in multiple charger scenario under the limit of maximum current from grid and maximum of charging requirements.

Besides the distribution current function, it also has the advantages like: adjusting parameter via physical button, controlling 100pcs chargers in maximum, sampling from both 3 phase grid, sampling from both CT and meter, monitoring in real time via multiple protection functions.

Specification

Input current | 0~300A |

Rated Voltage | 230VAC |

Voltage Range | 100-277V |

Rated Frequency | 50/60Hz |

Power consumption | 2W |

Max length of wire | 200m |

Display | 0.96 inch OLED |

Terminal cross-section (mm2) | 0.5 - |

Interface | WLAN | BLE(to be opened) |

Communication | RS485 |

Rated quantity of charger | 100 |

Dimensions (H x W x D) | df |

Product size

Installation instruction

Installation wiring diagram

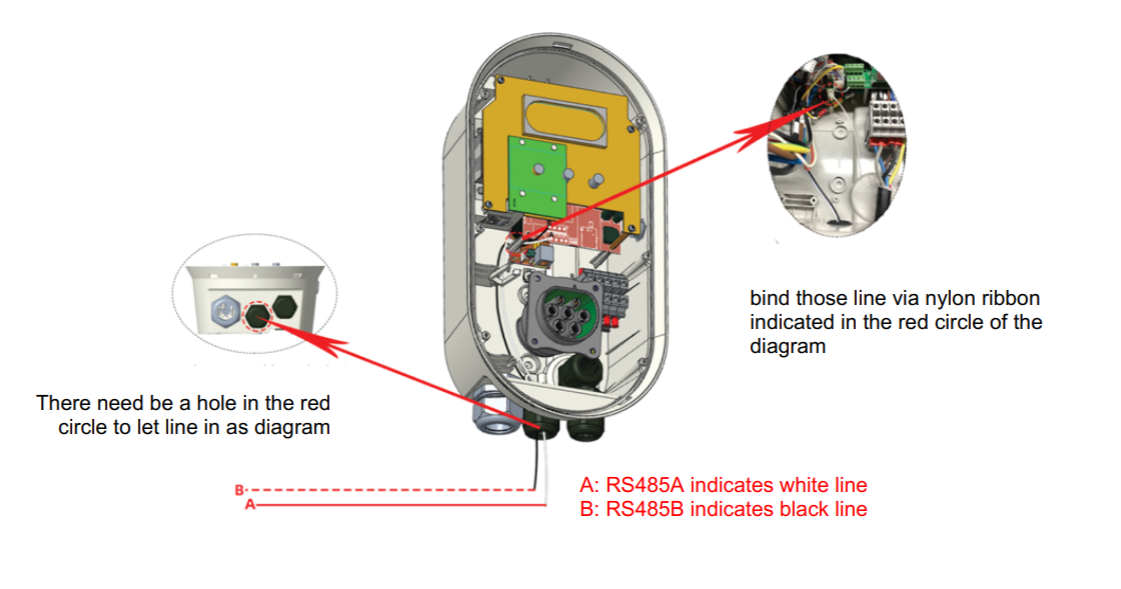

Twisted pair should be connected to the RS485 A/B terminals in the charger:

The last charger's A/B terminals must be shorted with 120 Ohm resistor (included with DLM HUB):

Interface introduction

Pin | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 |

Name | 485B | 485A | PG | 485B | 485A | PG | PE | N | L |

Func | Charger RS485 | Meter RS485 | Input Voltage | ||||||

| |||||||||

Pin | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 |

Name |

| CT+ | CT- | CT+ | CT- | CT+ | CT- | CT+ | CT- |

Func |

| Solar CT | L3 CT | L2 CT | L1 CT | ||||

Charger configuration steps:

| The charger station must be set into DLB mode. Choose phase rotation if single phase. |

Open and set DLB Mode parameter to ON in Morek EV Tool App

Select the value of Phase Rotation in the Morek EV Tool to determine the incoming line phase.

R is L1 of the power grid, S is L2 of the power grid, and T is L3 of the power grid.

"Not Applicable" is equivalent to RST.

The setting method is as follows:

Three phase charging station:

Select RST/RTS/SRT/STR

TRS/TSR according to actual wiring

Single phase charging station: Connect to Grid L1:Select RST/RTS; Connect to Grid L2:Select SRT/STR; Connect to Grid L3:Select TRS/TSR;

|

Download newest revision Morek EV Tool from Goolge or Apple APP store.

|

Install notice

The RS485 wire should link chargers in serial with one twisted pair not longer than 200m.

The end of RS485 wire should parallel 120 Ohm resistance.

The max charger count is suggested to be not more than 100.

Check the installation of current transformer (arrow direction).

DLM HUB configuration instruction

Interface

Main page:

3-phase | 1--phase | ||

|

|

| Item: Gird current Function: Display grid current and limit current |

The main page displays the grid current, and limit current, if three phase, it will switch between two pages.

Set page

| Item: Gird current Function: Modify the max limit current of the grid. Range: 0~300A |

| Item: Set phase Function: Modify the phase number of grid. Range: one/three |

| Item: Set method Function: Modify the sample method Choice: CT Range: 0~3000 |

| Item: Set method Function: Modify the sample method Range: 1200~57600 |

Alarm page

| Item: Show error Function: Error content Button :ignore the error |

| Item: Show warning Function: Waring content Button :ignore the error |

Buttons:

Switching Button: Click to switch pages or switch items.

Switching Button: Click to switch pages or switch items.

Adjusting Button: Change the item content or value.

Adjusting Button: Change the item content or value.

Confirming Button: Enter or exit set mode and confirm the modified item.

Confirming Button: Enter or exit set mode and confirm the modified item.

LEDs:

| Power Led / Green: Flash when powers on |

Com Led / Blue: Flash while sending messages | |

Alarm Led / Red: Flash when fails |

How to use

When the screen has no operation, the sampling current value is displayed as default. Switch the page through the switch button and click the ENTER button to select the interface. Select the setting item through the switch again, click the adjust button to the parameter value, and click the ENTER key to ensure and exit the setting.

For example: Change the CT rate

Click Switch button to switch to SET_METHOD page, then press ENTER button to enter set mode.

Click Switch button to switch to the modified item.

Click Adjust button to modify the CT rate value, then click enter to ensure and exit.

Usage Steps

Choose if it is three-phase or single-phase according to grid.

After installation, set the max home current first according to real demand.

Choose if it is sampled by CT or Meter, if by CT, sweet the CT rate from 0 to 9999, else if by meter, select the baud rate from 1200bps / 2400bps / 4800bps / 9600bps / 19200bps / 38400bps / 56000bps / 57600bps.

Check the wires again before starting to work.

Usage note

Before DLM HUB starts to work, make sure all chargers are in DLB mode, and connect to RS485 networks. If the charger is offline for one minute, the charger will ring 3 times, and display fault code 13.

Once the modified parameter is confirmed, it takes effect immediately, so make sure the parameter is correct before clicking the Enter button.

If a mistake occurs, the device will limit the set current to 6A and give an alarm by both screen and beep with an interval of 1.5s, if the mistake disappears, the device goes back to normal work, but the alarm will maintain 10 minutes with an interval of 5 seconds until user click Enter button.

If the user chooses one phase mode, only L1 takes effect default.

Troubleshooting

Error code

If there is a fault, the device will limit the 3-phase set current to 6A. Recover again after checking and clearing the fault.

Flash Pattern | Current Limit | Overcurrent | Current Drop |

Flash 1 time | L1 limit current 6A, but L1 real current >1.1*max_current | L1 overflow 150% | L1 current drop less than 0.9*max _current |

Flash 2 time | L2 limit current 6A, but L2 real current >1.1*max_current | L2 overflow 150% | L2 current drop less than 0.9*max _current |

Flash 3 time | L3 limit current 6A, but L3 real current >1.1*max_current | L2 overflow 150% | L3 current drop less than 0.9*max _current |

Flash 4 time | Communication fail | Sample fail | Communication recover |

Error handling

If one phase current exceeds max_home_current continuously, it might be following reasons:

The max home current is too small, or the phase mounts too many chargers.

Action: Increase the max home current, or decrease the charger number.

The CT clamp isn’t closed well, or malfunctions.

Action: Close the CT clamp again, or replace a new one.

The charger didn’t configure the phase position correctly.

Action: Config the phase position based on the real phase.

The CT rate is not correct, higher than the real value.

Action: Modify the CT rate based on the real value.

If the charger is offline, there may be the following reasons:

There are more than 100 pcs chargers online.

Action: Decrease the quantity of chargers.

The whole RS485 wire length is longer than 200m.

Action: Decrease the length of the wire.

The 485A and 485B are shorted.

Action: Find the shorted point, and fix it.

The charger’s RS485 function is damaged.

Action: Replace one new charger.

There is no 120 Ohm resistance at the end of the wire.

Action: Parallel a 120 Ohm resistance in the end of R485 wire.

To ensure the long- term stable operation of the equipment, please maintain the equipment regularly (usually every month) according to the operating environment. Ensure that the equipment operates in a dry and ventilated environment, regularly inspect the cables, and install and disassemble the equipment when powers off.

Check whether the join point of the input terminal is in good contact and whether there is any abnormality.

The equipment is maintained by professionals.

Was this article helpful?

That’s Great!

Thank you for your feedback

Sorry! We couldn't be helpful

Thank you for your feedback

Feedback sent

We appreciate your effort and will try to fix the article